Photopolymer resins – precision 3D printing for industry and prototyping

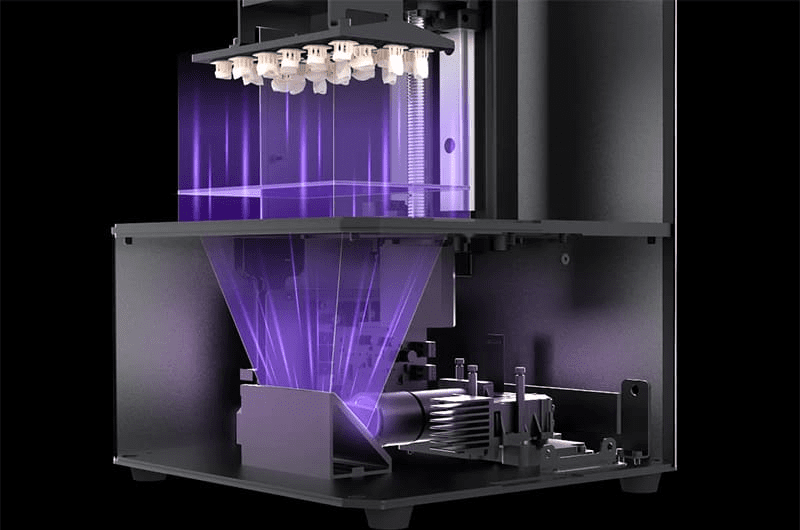

Photopolymer resins are materials used in 3D printing technologies such as SLA, DLP, and LCD, where the model is created by selectively curing liquid resin with UV light. Compared to classic FDM printing, resin technology offers significantly higher accuracy, surface smoothness, and the ability to reproduce very fine details.

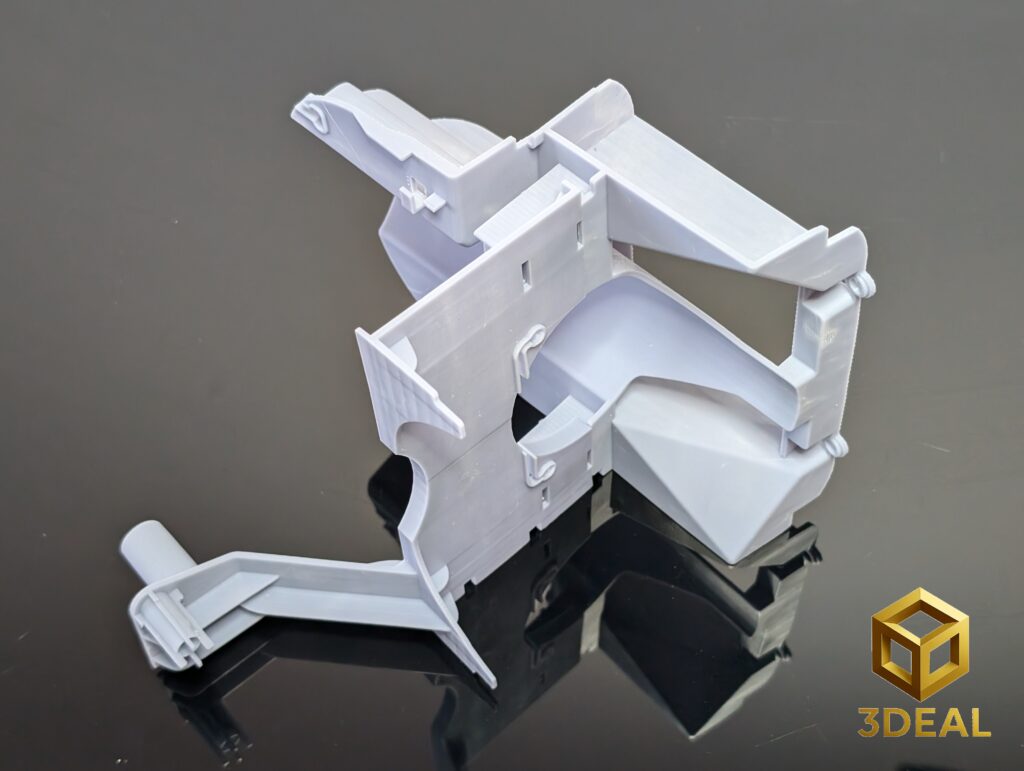

This makes photopolymer resins ideal for applications where precision, aesthetics, and repeatability are important—from technical prototypes and functional components to the medical and jewelry industries.

What are photopolymer resins?

Photopolymer resins are liquid polymer materials that cure under the influence of UV radiation. The printing process involves applying very thin layers (even 25–50 µm) and selectively exposing them to light according to the geometry of the 3D model.

The result is a printout with:

- very high resolution (accuracy of pixels on the printer screen or laser spot size),

- perfectly smooth surfaces and properties as in the case of injection molding,

- sharp edges and details,

- minimum dimensional tolerances.

Types of resins and their applications

Depending on the project needs, different types of resins are used:

🔹 Standard resins – basic resins with medium properties:

- ideal for visual and presentation prototypes,

- good surface quality,

- fast and economical printing.

🔹 Technical resins – harder and more resistant resins created for engineering applications

- increased mechanical strength,

- resistance to impacts and loads,

- used for functional testing and working parts.

🔹 Flexible and rubber-like resins

- imitate rubber or TPU,

- shock-absorbing elements, seals, covers.

🔹 High-temperature resins

- resistance to elevated temperatures (up to 160°C),

- molds, tooling, thermal testing.

🔹 Medical and dental resins

- certified for contact with skin or oral cavity,

- diagnostic models, surgical templates, temporary crowns.

Advantages of 3D printing with resins

3D printing with photopolymer resins offers a number of significant advantages:

- very high dimensional accuracy,

- excellent surface aesthetics without visible layers,

- ability to print complex geometries,

- an ideal solution for small-scale production,

- rapid prototyping without the cost of injection molds.

This makes SLA/DLP technology often chosen as an alternative to CNC machining or injection molding for small series (usually up to 1000 pieces of a given component).

Limitations worth knowing about

Like any technology, resin printing also has its limitations:

- necessity of post-processing (washing, UV curing),

- lower resistance to long-term UV radiation (depending on the resin),

- higher material cost compared to FDM.

However, selecting the appropriate resin and technology allows you to fully adapt the print to real working conditions.

Where does resin printing work best?

Photopolymer resins are especially recommended for:

- functional prototypes,

- elements with high aesthetic requirements,

- precision and assembly parts,

- medical and dental models,

- short production series,

- alternatives to injection for small volumes.

Summary

Photopolymer resins are advanced 3D printing materials that enable the implementation of projects requiring high quality, precision, and repeatability. Thanks to the wide range of available resins, it is possible to tailor mechanical, thermal, and visual parameters to a specific application.

If you want accurate, professional 3D prints, contact us and we will find the right material for you!